The Basics of CNC Machining

CNC Machining is a method of producing complex parts using computers. It can be done with a variety of materials, including wood, plastic, metal, and even wood composites. Depending on the nature of the job, a CNC machine can utilize a range of machine tools. A CNC operator needs a diverse skill set to be successful, from mechanical design to an eye for detail. They must have excellent reading and writing skills, as well as be able to work with technical drawings.

CNC operators report to their assigned work center each morning and load supplies to start the day. During the shift, they talk to the previous shift operator, catching any design flaws or potential risks when using different materials. Teamwork is also important for the CNC operator, who can quickly plan for audits and tool changes. High-pressure water jets can cut through a variety of hard materials. Sometimes, they're mixed with sand or other abrasive substance to shape factory machine parts.

Before beginning the day, CNC operators must load their equipment and supplies. They also need to make sure the work center is properly maintained by ensuring that it is free of debris. During the first couple of hours, they may need to make a few rounds of cuts with the tools to make sure they're in the right places. In some cases, it's necessary to manually remove parts from the machine, so that they don't get damaged during the process.

In addition to the advantages of CNC machining, this technology can also be used to produce a wide range of materials and finishes. One of the biggest challenges of CNC machining is the computer's assumption of perfectionism. The best CNC machines can create a part that's close to perfection, but a few minor errors can cause problems. Then, they need to be tested. Once the machine is tested and approved, the program is ready for production.

The first step in the CNC process is preparing a CAD file. This file consists of the parts and their dimensions. The CAD file is used to make the model. The software will then decide on the optimum cutting parameters. The parameters are crucial for the precision of the part. The software will also determine whether the part requires a sharp blade or a fine-toothed axes. This information will be used to create a precise CNC machining.

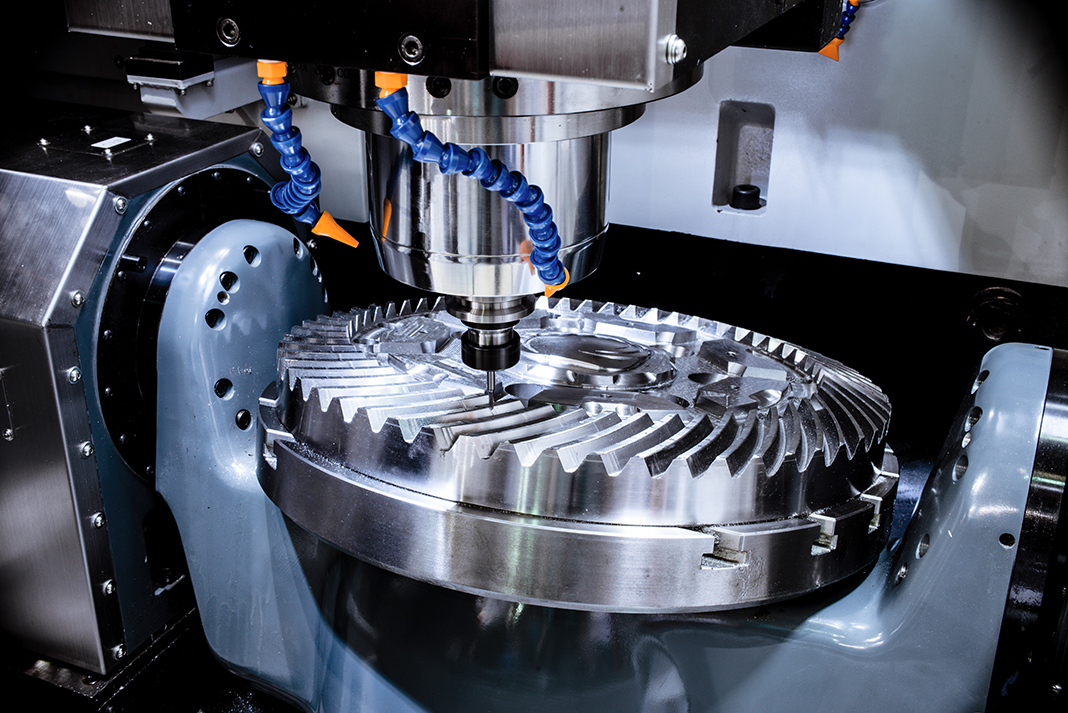

CNC machines can make any part with complicated shapes. The computer programs that control the process are called G-codes. The software controls the machines' movements and determines the parameters. The software will also provide an accurate cut, and will also provide a complete file of the finished product. The computer is then programmed to produce the required part. The software will automatically generate the G-code and M-code from the CAD file.

评论

发表评论